Prof Matt Boyle OBE, Executive Chair, Driving the Electric Revolution Industrialisation Centres

2023 was a challenging year for UK manufacturing, with the sector experiencing the second-highest number of administrations of any business sector in the country during the first six months. This isn’t surprising given the challenging set of circumstances manufacturers are facing including soaring energy prices, material costs, and inflation.

The industry hoped to start this year in a more favourable position with data showing factory outputs increased for the first time in months last November when the government also announced the £4.5billion Advanced Manufacturing Strategy to support the industry. Recent data however shows December marked more setbacks to growth as output and employment fell. A multitude of challenges exist – whether that’s staying competitive in an international market, access to funding, potential political U-turns in the wake of a 2024 general election, or meeting supply chain pressures to decarbonise – this year is set to be one that sets the tone for the sector in decades to come.

Industry collaboration – an opportunity to reduce costs and boost profit

As well as facing a similar set of challenging economic circumstances, much of the manufacturing supply chain are under similar pressures to innovate in Power, Electronics, Machines and Drives (PEMD) towards electrification. When looking to adapt their supply chain but de-risk corresponding investments, one approach businesses can take is to pool resources and collaborate with other industry players to find solutions in an efficient and cost-effective way.

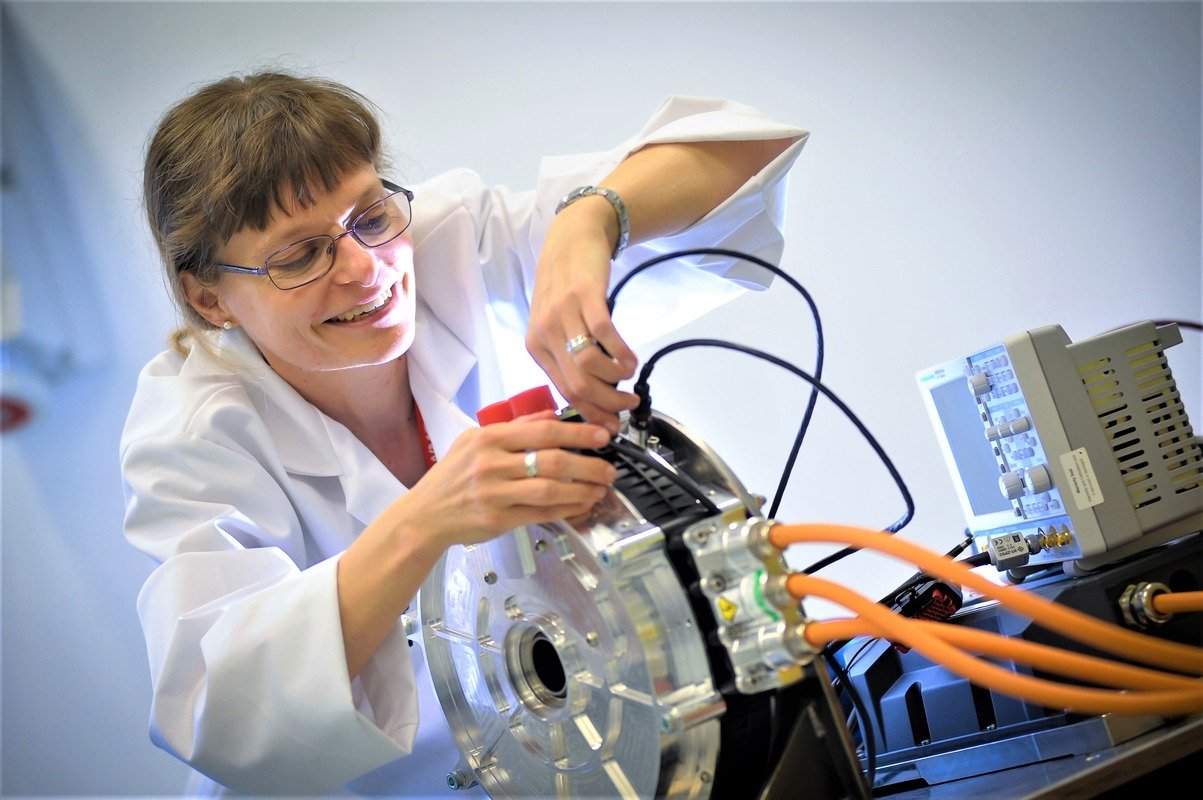

Driving the Electric Revolution Industrialisation Centres (DER-IC) are an industry network who support development and innovation of manufacturing within PEMD technologies to break down the barriers businesses face when adopting new processes and technologies and scaling up operations. DER-IC provides open-access equipment, specialist knowledge, offers access to an extensive partner network, and fosters collaboration across the PEMD manufacturing supply chain. DER-IC has supported and continues to support SMEs/manufacturers to prototype, test, develop, and plug the gaps they need to fill to remain competitive in a market that’s racing towards electrification.

2024 – putting the pedal to the metal

The need for electrification – and the corresponding supply chain changes – will increase exponentially this year and it will be a challenge for industry to satisfy demand. British manufacturers will need adequate capital and skilled labour to avoid losing business to other markets.

Giving manufacturers access to the £4.5 billion government funding before 2025 would go some way to help but it will still take more funding to compete with markets like Germany and America. The industry would also benefit from an over-arching Industrial Strategy to link up the corresponding sections of the Advanced Manufacturing, Battery, and Semi-conductor Strategies.

It’s not just a question of needing capital and strategic direction either, the UK manufacturing industry can only ‘put the pedal to the metal’ this year if they can successfully upskill, reskill, and fill the pipeline that creates the workforce of the future, which is something we continually work with the DER-IC network to develop and support.

Adequate capital and labour won’t be enough on its own though, UK manufacturing also needs a PR campaign to attract the engineers of the future. Recognition of the value that engineers bring to society – including its electrification – will make it a more attractive profession to young people and drive society’s desire to understand how things work in the first place as well as how they are maintained and repaired.

An international playing field

It was positive to see government announcements in 2023 that focussed on encouraging foreign direct investment – the race to electrification is a global one. Putting policies in place which attract manufacturing SMEs to the UK to grow and develop their businesses is going to support our supply chain from both a skills and product perspective.

Where the industry can’t upskill domestically, or attract talent from abroad, manufacturing will have to consider automation. Investing in and utilising artificial intelligence (AI) will play a key part in the UK manufacturing industry’s ability to cut costs, stay profitable and compete internationally. AI is already being deployed in factories around the UK, sensors developed by tech firm Augury were introduced at the PepsiCo factory in Coventry last year to listen out for indications of hardware faults, having been trained to recognise sounds of weary machines that risk bringing production lines to a grinding halt.

The outcome of a general election this year will be another marker of what direction UK manufacturing might take. Regardless of this, the goal for global electrification isn’t going to change, much of the supply chain has invested billions in transitioning away from fossil fuels – and this won’t stop now.

The UK manufacturing industry is changing rapidly, which is why it is key the industry collaborates and taps into networks like DER-IC to join up the dots. The global economy is currently in a race to electrification and UK manufacturing has everything to play for, despite recent challenges, which is why this year you’ll see them going all in.