DER-IC University of Nottingham

The University of Nottingham received funding for new equipment from DER that is housed at the Power Electronics and Machines Centre (PEMC). The PEMC offers purpose-built laboratories for the Power Electronics, Machines and Control Research Group, the largest such group of researchers in the world, and sits at the heart of the University’s commitment to establishing Nottingham and the East Midlands as a hub for the translation of net zero technologies from research bench to real world solutions.

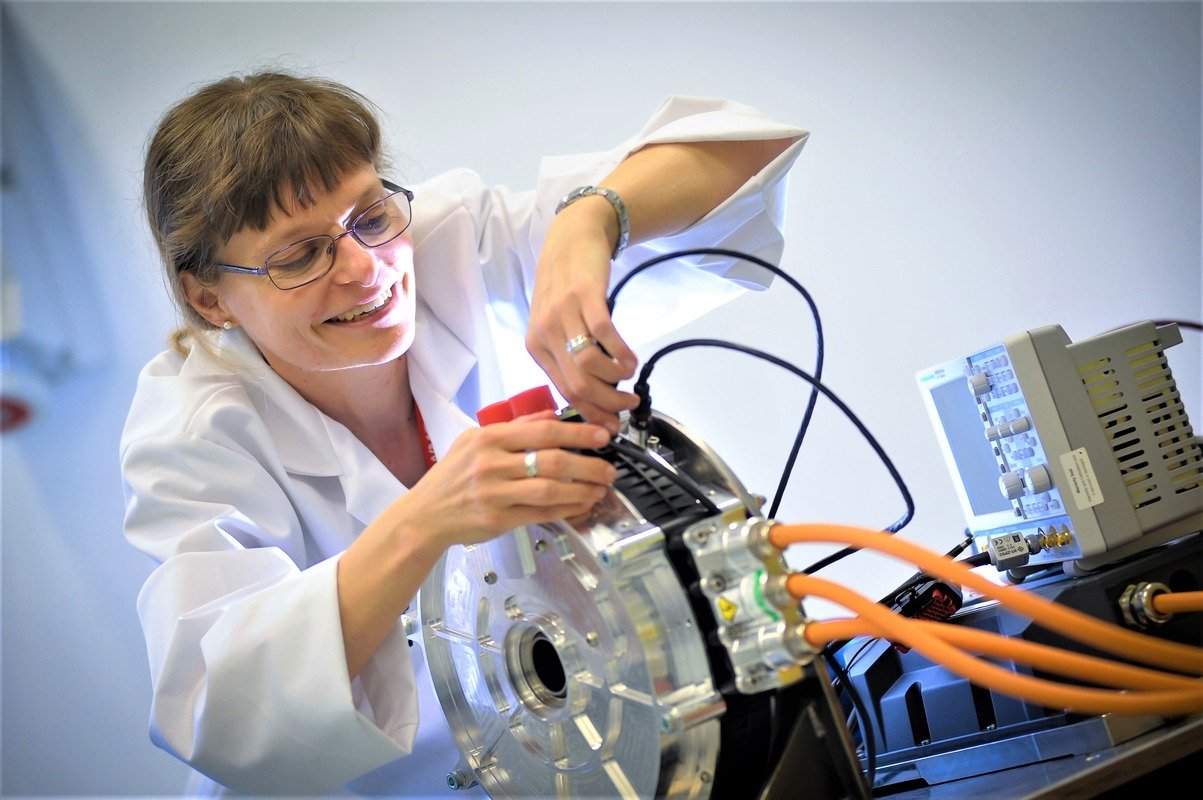

DER has enabled development of the ‘Future Factory for High Performance Electrical Machines’ – a facility for developing manufacturing processes for high performance electrical machines, equipped with a number of winding machines including a litz-wire winding process, advanced hairpin solutions for high frequency drives, fully customisable Vacuum Pressure Impregnation (VPI) and a range of magnetic and insulation test equipment.

DER-IC University of Warwick

The University’s DER-funded equipment is located within the School of Engineering and comprises a power electronics module assembly, reliability and failure analysis facility. The equipment is focussed on enhancing the reliability of Wide Band Gap (WBG) power electronic modules and allows the technology for reducing size, weight and cost across all sectors to be better understood for volume production.

Power Electronics Module Assembly, Reliability and Failure Analysis Facility for high power WBG devices

- Scanning acoustic microscope

- Environmental chamber for reliability testing

- Industrial data logging equipment/Hardware in the Loop (HIL)

- De-capsulation facility

- Power cycling facility

- Fibre Bragg grading system

- Thermal camera

DER-IC WMG

WMG is an academic department at the University of Warwick and the leading international role model for successful collaboration between academia and the public and private sectors. The funding from DER, additionally supported by the High Value Manufacturing Catapult, has established a Winding Centre of Excellence, providing capability for UK based OEMs and SMEs to develop eMachine solutions.

Winding Centre of Excellence

- Equipped to manufacture all types of windings at production quality, specialising in hairpin stators

- Discrete hairpin winding and continuous hairpin winding

- Distributed winding and winding of synchronous wound rotors

- Concentrated windings for radial and axial flux machines

- Laser welding for busbars and connections

- Insertion robot for magnetised and unmagnetised magnets for rotor assembly

- Magnetiser, rotor assembly to hub, trickle impregnation, stator loading into housing and curing ovens

- In-process testing of electrical, thermal and mechanical effects