Location: Midlands

WMG is an academic department at the University of Warwick and is the leading international role model for successful collaboration between academia and the public and private sectors, driving innovation in science, technology and engineering, to develop the brightest ideas and talent that will shape our future. They work with over 1000 companies cross-sector.

WMG is also a High Value Manufacturing Catapult, driving growth and productivity by accelerating and de-risking innovation to deliver powerful solutions for industry. WMG HVMC leads on Net Zero Mobility, with major roles in Energy/Electrification, eCAM, Digital Technologies and Surface Transportation.

WMG provides multi-sectorial cross-regulatory expertise to inform policy and standards development and help provide thought leadership to the UK government to drive the technology landscape of the future.

The area of efficient electrical energy conversion has become critical in the development in energy systems. Renewable energy sources will be hooked into electrical energy networks using power electronics and power transmission, and distribution will become more reliant on power electronics to efficiently control and regulate electrical energy in an already congested electrical network. All forms of transport are becoming dependent on power electronics to provide more sustainable vehicles.

Key strengths and unique capabilities

- Fundamental materials and device research

- Power systems

- Converters

- High power energy storage

- Wireless induction charging

- End applications and intermediate technologies

- Application of aluminium and composite technologies

- Significant characterisation capabilities, including high power XRD

- Development of non-grain oriented electrical steels

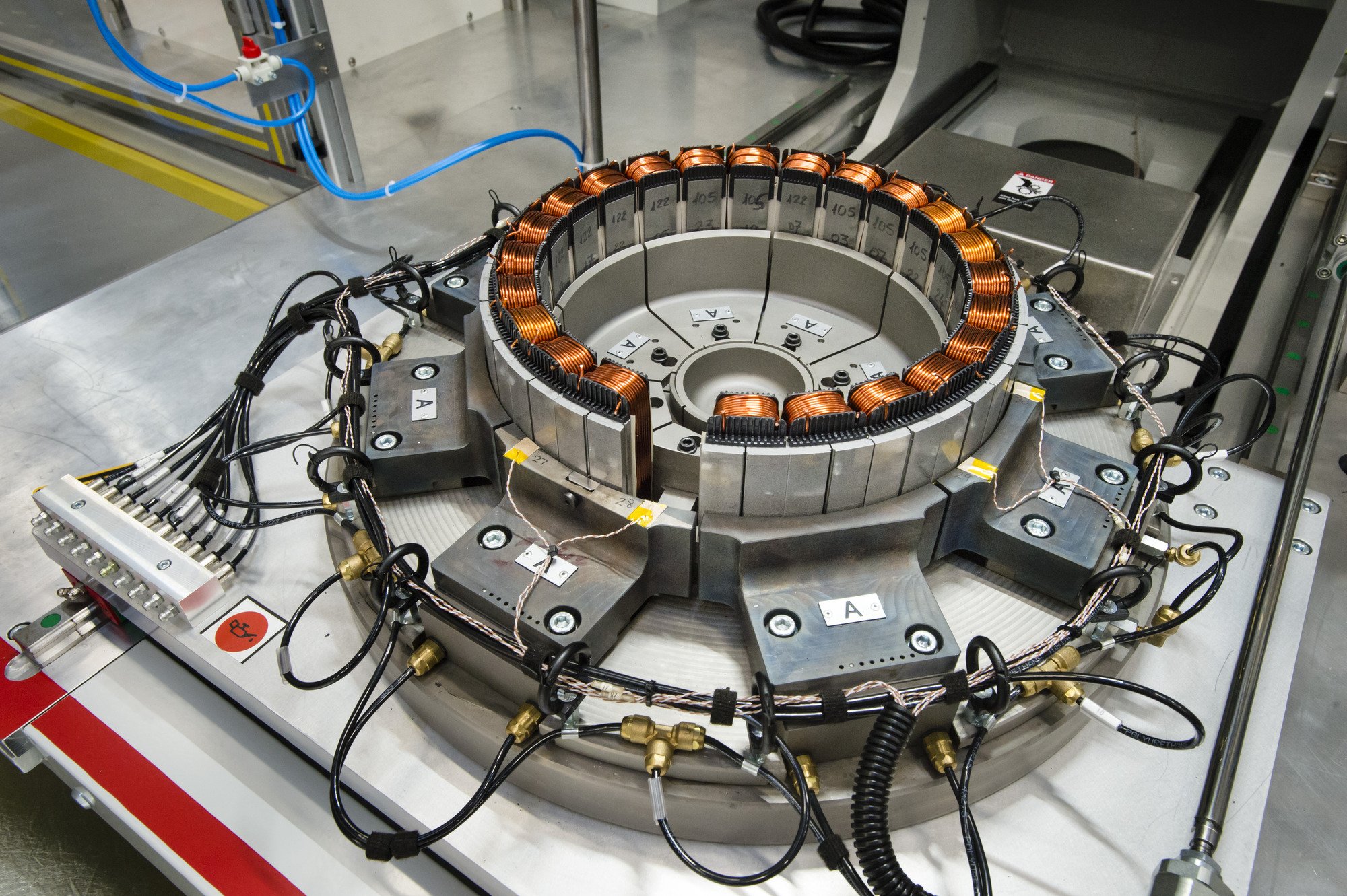

- Magnetisation and calibration of rotor/stator

- Stack, rotor and stator assembly

- Extensive focus on winding technologies for e-machines

- Process capability development

- System modelling and integration – battery, machines, power electronics

- Full testing capability for thermal, dyno, high altitude on PEMD

Equipment

Equipped to manufacture all types of windings at production quality, specialising in hairpin stators:

- Discrete hairpin winding and continuous hairpin winding

- Distributed winding and winding of synchronous wound rotors

- Concentrated windings for radial and axial flux machines

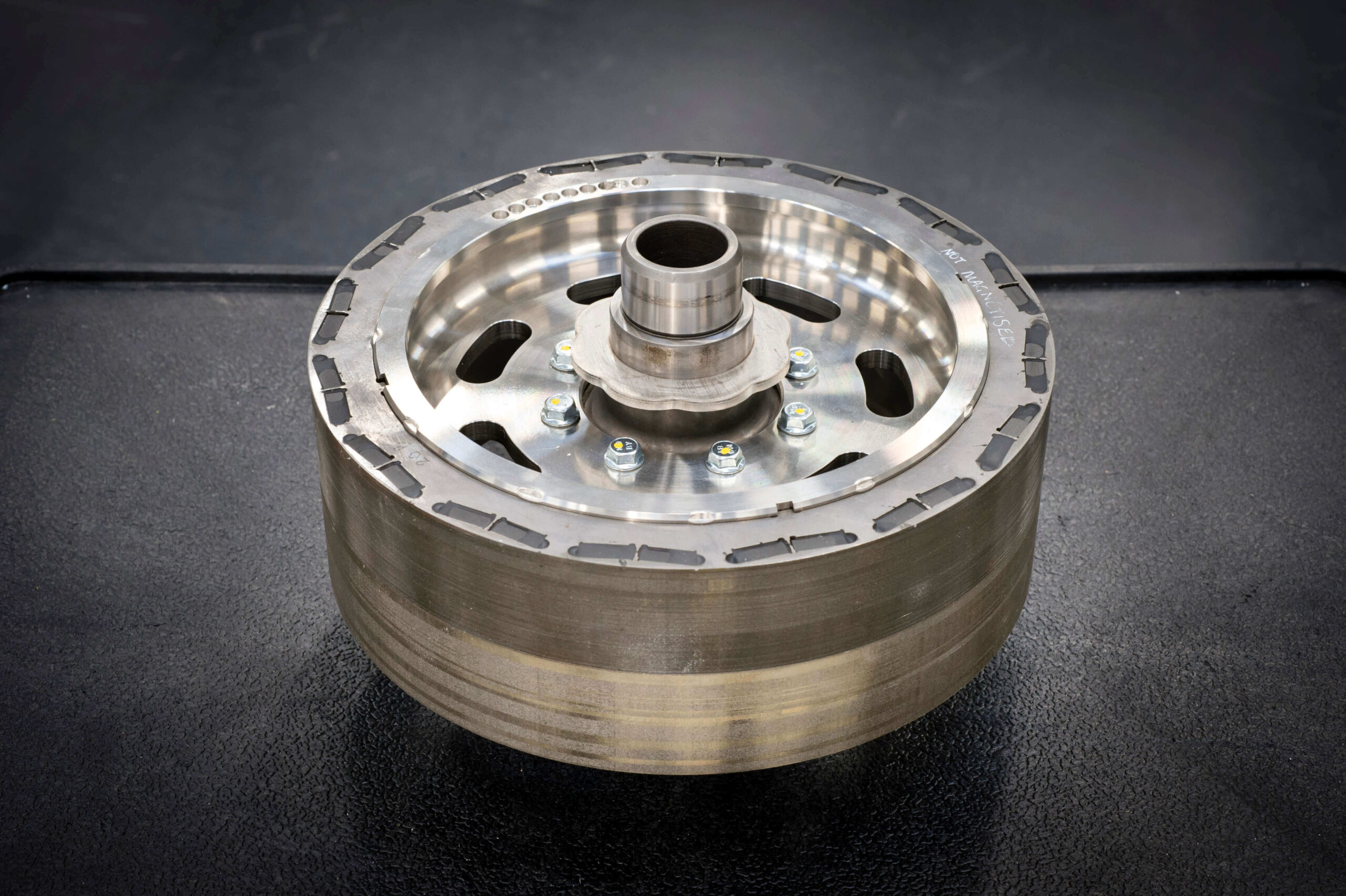

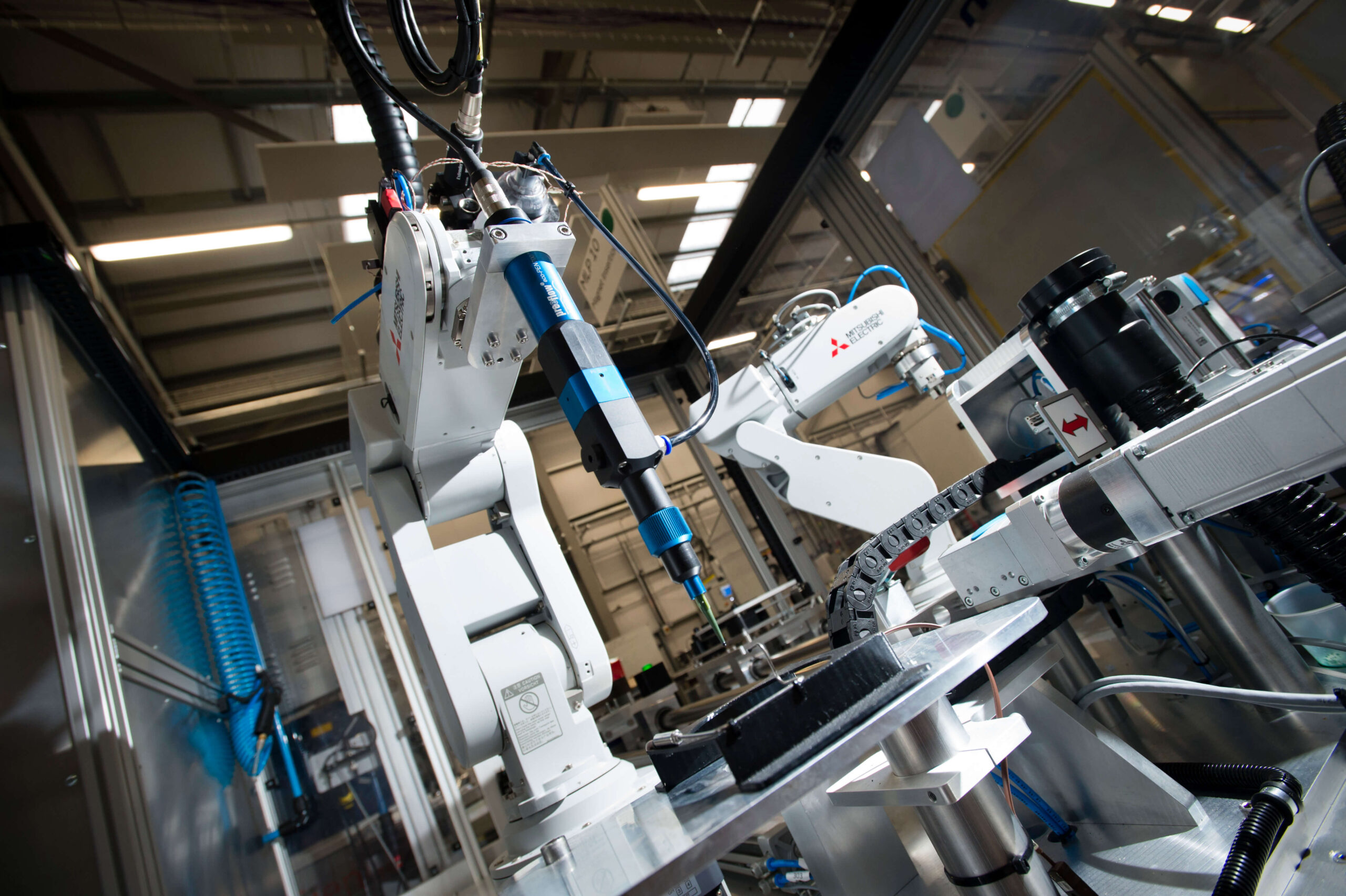

- Insertion robot for magnetised and unmagnetised magnets for rotor assembly

- Magnetiser, rotor assembly to hub, trickle impregnation, stator loading into housing and curing ovens

- In-process testing of electrical, thermal and mechanical effects

- E-machine development

- E-machine components development

- Two Hybrid engine test cells

- Climatic chamber for electrical dynamometer

- Electrical dynamometer high speed / low speed

- Inverter test cell