Location: Scotland

As part of the multi-award-winning University of Strathclyde and the UK Research and Innovation (UKRI) funded DER-IC – Scotland, PNDC links into extensive research expertise and laboratories supporting the development of power electronics, high-efficiency/high power conversion, electrical machines, condition monitoring and lifecycle analysis, superconducting machines and aero electrical resilient power systems.

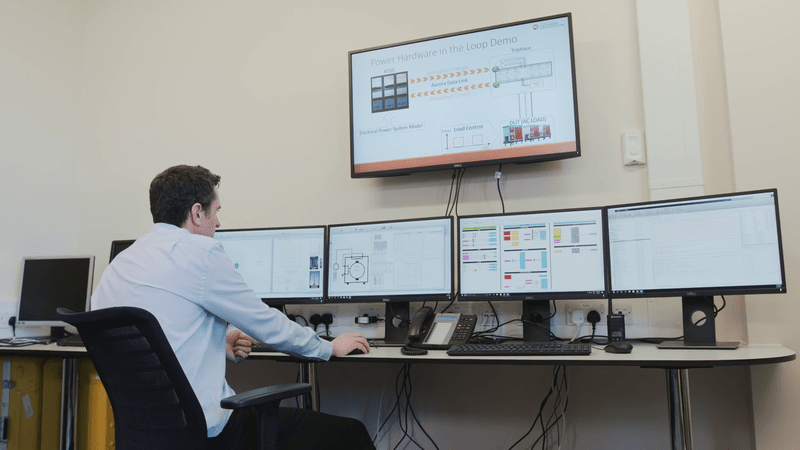

Their world-class innovation environment accelerates the de-risking and validation of new products and systems for the electrification of high power, high integrity transport. PNDC’s unique facility supports integrated electrical system, sub-system and device testing utilising Power Hardware in the Loop (PHIL) capability and expertise, with an extensive supply chain network from component manufacture to systems integrators, enabling a testbed for supply chain development.

Key strengths and unique capabilities

- Simulation

Providing real-world simulation and validation of critical functionalities and dependencies. - Device test and evaluation

Full-service facility offering tailored device-level testing and evaluation. - Sub-System/System test and evaluation

Expertise across a wide range of test environments and evaluation frameworks. - Commercialisation

For SMEs, Tier 1 and OEMs, PNDC’s extensive experience in de-risking, validation, and pre-compliance testing supports the journey from research to commercialisation.

Lightweighting/composite structures

Through PNDC’s links with the University of Strathclyde’s Lightweight Manufacturing Centre, they are able to offer advice and prototyping services in lightweight composite structures.

- Simulation

System- and subsystem-level simulation, including real-time and hardware in the loop (HIL) simulation. - Device test and evaluation

Machine testing with or without an inverter, including vibration analysis. Power electronics testing, including with virtual machines or power systems. - Sub-System/System test and evaluation

Full or partial system testing, including real-time power hardware in the loop simulation of the rest of the system, including emulation of control signals. Facilities to include testing of batteries and hydrogen fuel cells. - Supplier qualification

Testing and characterisation of components from different suppliers within an emulated electrical system. - Cryogenics/superconductivity

The facility is equipped to handle cryogenic and superconducting systems, and we work closely with the University’s Applied Superconductivity Laboratory, ASL Strathclyde.

The high power integrated electrical propulsion and powertrain accelerator supports development, manufacture and test of Megawatt (MW) scale Power Electronics, Machines and Drives (PEMD) for high power applications in transport (marine, aerospace, off highway, rail and truck/bus) and energy through expansion of the existing multi-MW power hardware in the loop testing capability at PNDC.

Equipment

MW-scale innovation and testing using DER-IC funded MW-rated dynamometers and MW-scale power supplies

PNDC brings together academia and industry in innovative collaboration. It has enhanced measurement, frequency and voltage control with a unique fault throwing/disturbance feature and can enable ‘smart grid’ networks of the future in accelerated time scales. The facility includes:

- Control room

- Low-voltage (LV) network

- Load banks

- Urban cables

- Primary substation

- Packaged substation

- Overhead lines

- Mock impedance