Rare earth materials used in high performance magnets for electronic devices will be recycled in a new facility at the University of Birmingham.

The plant is a major milestone in the commercialisation of rare earth magnet recycling technology in the UK, offering a closed loop recycling process, taking magnets from end-of-life electric motors, electronic waste and components, reclaiming the valuable neodymium, iron and boron they contain, and reforming it back into commercial-grade magnetic materials.

Rare earth magnets play a critical role in electronics devices from hard disk drives and loudspeakers to wind turbines, but currently less than 5 per cent of magnets are recycled. As clean energy technologies become increasingly prevalent, it is vital to develop processes to ensure a sustainable supply of these materials and reduce dependency on virgin mined metals.

The plant has received state-of-the-art new equipment funded by UK Research and Innovation’s Driving the Electric Revolution Challenge, to support a more secure UK supply of recycled rare earth magnets from processed oxides. The University is a partner in Driving the Electric Revolution Industrialisation Centres, designed to support the UK in becoming a centre of excellence and innovation in power electronics, machines, and drives (PEMD).

Key to the plant’s design is a patented process, developed at the University of Birmingham, which uses hydrogen to liberate and break down the used magnets into an alloy powder for remanufacture. Called HPMS (Hydrogen Processing of Magnet Scrap), this process is based on the hydrogen decrepitation process developed at the University by the late Professor Rex Harris and was first tested in the laboratory using an old washing machine drum to extract the rare earth alloys from products such as hard disk drives, speakers and electric motors and separate it from other bits of plastic and metal surrounding the magnet.

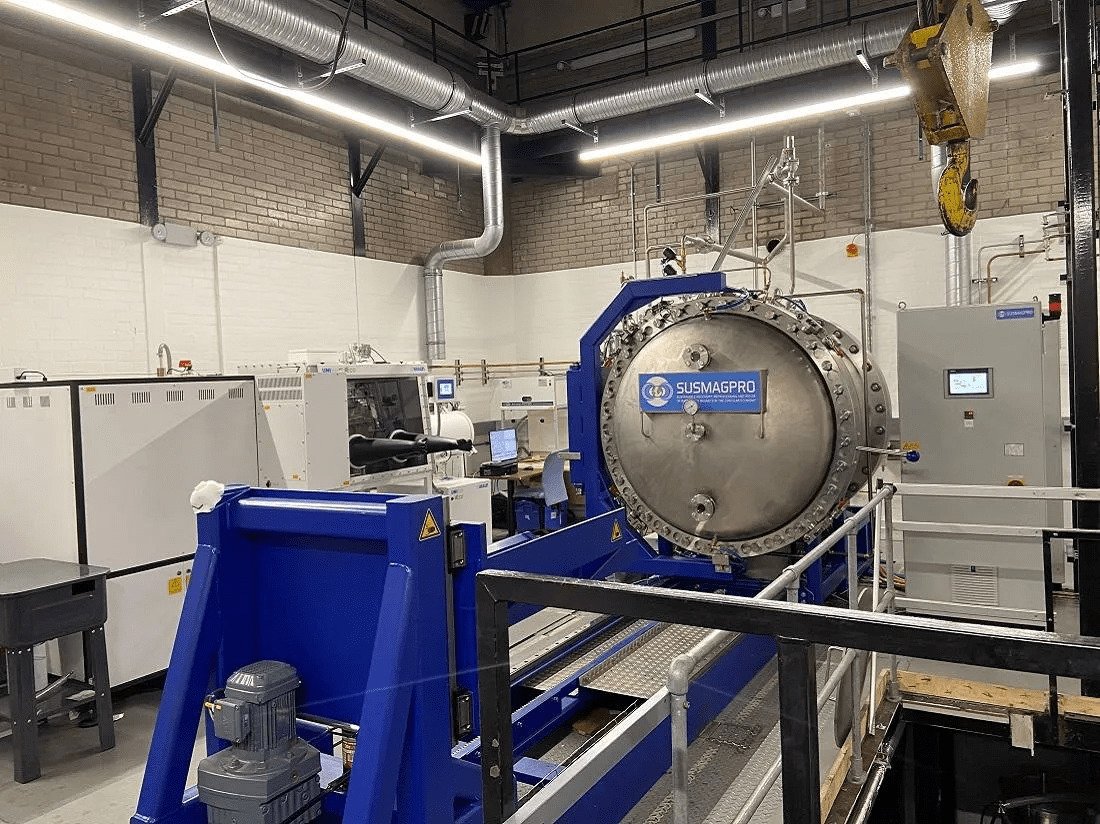

Following initial successes, the technology has now been scaled up to the pilot scale – this facility has received significant funding via the EU Horizon 2020 project SUSMAGPRO, one of the largest magnet projects in Europe.

In the new facility, a 1,300-litre sealed drum is able to process up to 100kg of magnets per day. Crucially, the resulting powder is de-magnetised during this process, so can then be refined further before going through a sintering process, in which the reclaimed materials are heated to form bars and remagnetised.

Professor Allan Walton, Co-Director of the Birmingham Centre for Strategic Elements and Critical Materials, said:

“This pilot plant paves the way for the UK to take a leading role in high performance magnet recycling. Alongside the technologies and equipment we have developed, is a wealth of industry and research expertise. These partnerships form a solid foundation for this new industry to succeed.”

In its initial phases, the plant will recycle magnets taken from hard disk drives, which are removed using robotic disassembly techniques developed with European Metal Recycling Ltd, as part of an EU-funded project. The range of products that can be recycled will expand as the component disassembly processes develop further.

Dr Vicky Mann, Research Fellow in the School of Metallurgy and Materials, said:

“While disk drives are plentiful and the magnets within them are valuable, they each weigh about 25 grams. So our ability to expand the number of different components we can recycle will really drive the success of this project. A wind turbine, for example, contains a magnet weighing several tonnes, offering a critically important source of rare earth magnets.”

The plant is an important step towards opening the UK’s first full scale remanufacturing facility at Tyseley Energy Park, funded by UK Research and Innovation (UKRI), which is due to be completed in 2023.

The patented technologies in the process have been licensed to HyPromag Ltd, which will be the facility’s primary industrial user, helping to operate the plant and establish the supply chain.

HyProMag Operations General Manager Nick Mann said:

“This pilot plant enables us to demonstrate not only the potential of the HPMS process, but how efficient the end-to-end production line can be. It will also enable us to refine and streamline the production line ahead of launching our full scale facility at Tyseley.”

Also key to success will be a second UKRI-funded project – Secure Critical Rare Earth Magnets – which will establish a secure supply of rare earth magnets from end-of-life sources such as robotics, automotive and loudspeakers.